Characteristics and advantages:

-

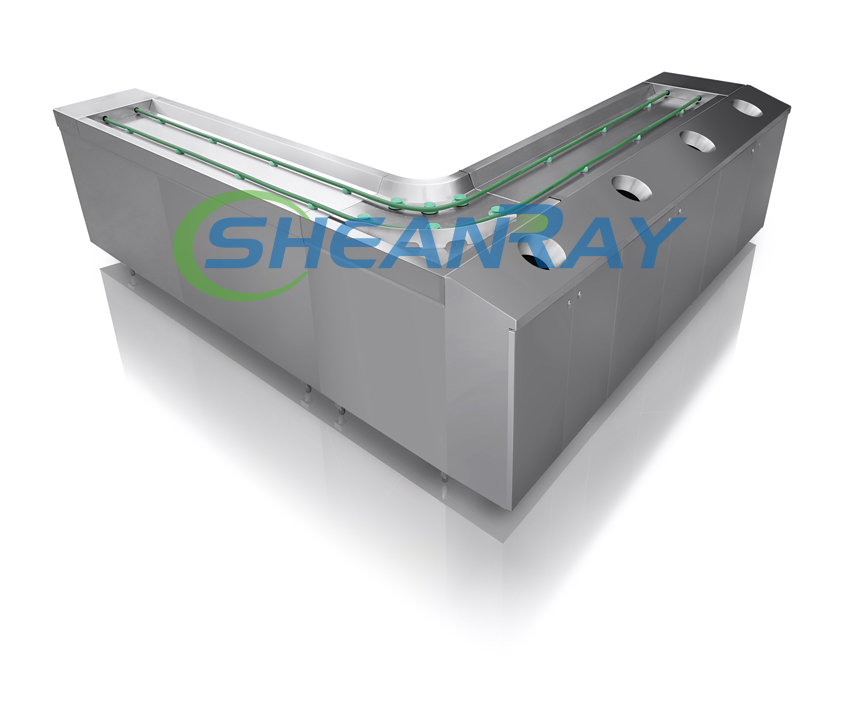

Two parallel round cords

drive the flat bottom tray to slide on the stainless table-board via the PP

driving wheel, the process of

transmission is noiseless.

-

Conveyor automatically

delivers tableware into Dish Washing Room, which reduces operator’s labor

intensity.

-

Equipped with

international brand gear motor and frequency converter, with frequency

conversion and stepless speed regulation and soft-starting function, running

stably and reliably.

-

Flexible module

combination design, customize size and turning angle according to the on-site

space.

-

Adopt highly elastic,

anti-wear and thickened polycord, embedded with intensified cable cores, which

are more endurable and long-lasting.

-

Circuit over-loading and

electricity leakage safety protection design ensures safe operation.

-

Real-time transfer speed

digital display, external speed governing potentiometer, the operation is

simple and clear at a glance.

-

Built-in drawer type

residue basket, easy to clean.

-

Optional 3 cord type,

throwing cabinet for small parts, noise enclosure and height limit device, etc.

to meet the different demands of the clients.

Requirements on installation connection:

-

Requirement on electricity installation: 220V/1Ph/0.4~2.4KW

Applicable places:

-

Large-scale employees’ canteen, school and other places

Parameters:

Model TC480L

Width of trays ≤350mm

Transmission speed 5~20M/min

Turning angle 85°~180°

Slope ≤6°

Height 880mm/920mm

Power supply 220V/1Ph

Power 0.4~2.4KW

Turning radius ≥650mm